Company

The necessity to increase productivity and quality control at production units opens the need for the development of especial solutions. Namely customize tools, control equipment, manipulators and automations.

MDU was created within this context. Essentially by the demand for special production solutions for the production line of Autoeuropa, a Volkswagen car factory located in Portugal, near Lisbon.

Now, with nine years of experience on the conception and manufacturing of special equipments the scope of our clients has increased. Presently, we still work in innovation projects for several diferent markets, such as: automobile industry, aeronautics, pharmaceutical, heavy industry handling systems, software development, etc.

The continuous grouth of our company leads to us to the acquisition of several manufacturing tools, software and assembly installations.

Working method

MDU

supplies "turn key" solutions. For client demanded projects or coordinated

and developed together. Some projects start only with the need for a

solution. The design of the equipment to solve that solution arises with the

correct interaction between client and our project department.

Starting from the specifications the work follows the steps:

Main equipments are supplied with a operational manual, including:

|

|

Objective

To assure the main priorities to the client the following steps are

considered:

| |

Project

The mechanical project is developed using Solid Works

design software.

Each part, component and assembly is designed using this software. This

technique allows the client to see the final solution before it is built. It

is possible to change the equipment before it is built. A significant cost

reduction is possible and turns the clients acceptance of the equipment

easier.

The same

approach is used to make special studies on existent equipments at the

client facilities. Allows to understand possible changes and investments.

For new products or simply to increase production or quality.

Stress analysis on line carriers doe to some design changes

|

Power train assembly line |

|

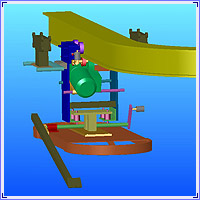

Equipment to assembly automatic gear boxes |

|

Motorised battery chargers |

|

|

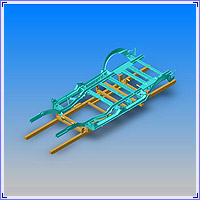

Line skids changed to work with new model |

|

Production

The mechanical parts are

built at a

several MDU's

partners.

All the wending, assembly, electrical and pneumatical circuits are

done at our installations. Including tests and introduction to

client.